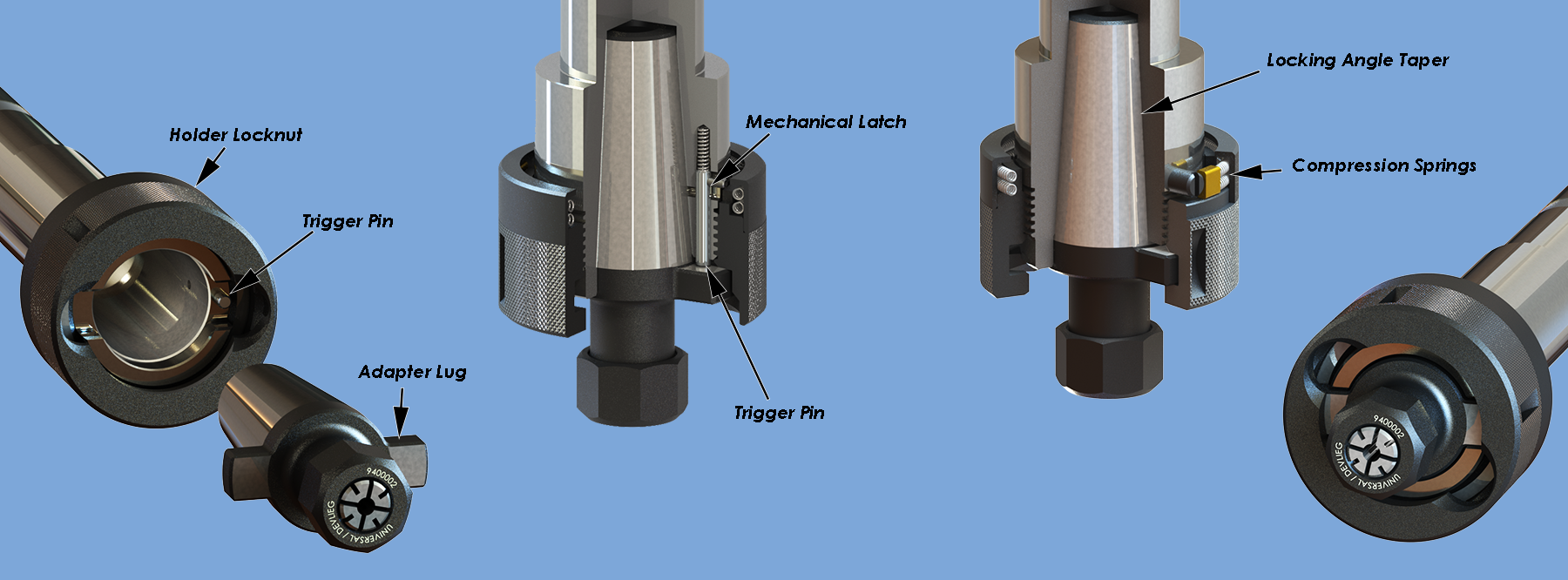

As the holder locknut is opened, coil springs are compressed. When the open position is reached, a mechanical latch holds the nut open. This latch is operated by a trigger pin.

The trigger pin is depressed by one of the tool adapters lugs as the adapter is inserted into the spindle socket. When the trigger pin is depressed, it releases the compression springs.

This causes the spindle nut to rotate, which draws the adapter into the locking angle taper socket. Since locking forces are always present, the nut continues to tighten under load.